How to Fix Warping and Layer Adhesion Issues in 3D Printing

Share

Introduction

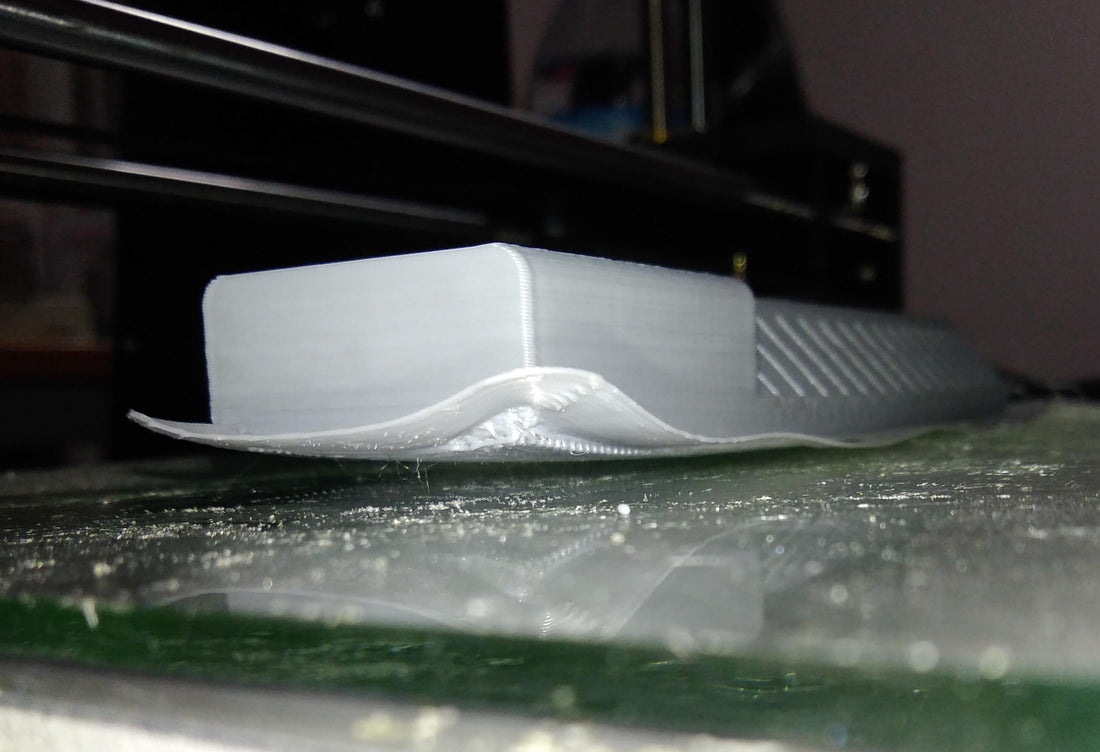

Warping and poor layer adhesion are common issues in 3D printing that can ruin an otherwise perfect print. Warping occurs when the corners or edges of a print lift off the build plate, causing deformation, while poor layer adhesion results in weak prints that easily break apart. If you’ve struggled with these problems, you’re not alone. In this guide, we’ll explore the causes of warping and layer adhesion issues and provide practical solutions to help you achieve strong, warp-free prints.

What Causes Warping and Poor Layer Adhesion?

Understanding the root causes of these issues is the first step toward fixing them. Here are the most common culprits:

- Uneven Cooling: Rapid or uneven cooling of the print can cause layers to contract and warp.

- Incorrect Bed Temperature: A bed that’s too hot or too cold can lead to poor adhesion and warping.

- Material Properties: Some materials, like ABS, are more prone to warping due to their high shrinkage rate.

- Poor Bed Adhesion: If the first layer doesn’t stick properly, the print is more likely to warp or detach.

- Environmental Factors: Drafts or temperature fluctuations in the printing environment can exacerbate warping.

Step-by-Step Solutions to Fix Warping and Layer Adhesion

1. Optimize Bed Temperature and Adhesion

Use a Heated Bed: For materials like ABS, a heated bed is essential to prevent warping. Set the bed temperature according to the filament manufacturer’s recommendations.

Improve Bed Adhesion: Apply adhesives like glue sticks or hairspray to ensure the first layer sticks properly. Alternatively, use a build surface like a PEI sheet for better grip.

2. Control the Printing Environment

Use an Enclosure: An enclosure helps maintain a stable temperature around the print, reducing the risk of warping. Check out the Creality 3D Printer Enclosure for a reliable solution.

Eliminate Drafts: Ensure your printer is placed in a draft-free area. If necessary, print a custom draft shield directly in your slicer to block airflow.

3. Choose the Right Material

Switch to Warp-Resistant Filaments: If you’re using ABS and experiencing warping, consider switching to a less warp-prone material like PLA or PETG. For high-quality options, try PLA Filament or PETG Filament.

Dry Your Filament: Moisture in filament can weaken layer adhesion. Use a filament dryer to remove moisture before printing.

4. Fine-Tune Your Slicer Settings

Adjust the First Layer Settings: Increase the first layer height and extrusion width to improve bed adhesion.

Use a Brim or Raft: Adding a brim or raft to your print can help anchor the edges and prevent warping.

Lower the Print Speed: Slower print speeds allow each layer to adhere better, reducing the risk of warping.

5. Post-Processing Techniques

Annealing: For PLA prints, annealing (heat-treating) can improve layer adhesion and reduce warping.

Coating with Epoxy: Applying a layer of epoxy resin can strengthen the print and smooth out imperfections.

Practical Tips to Prevent Warping

- Level the Bed: Ensure your build plate is properly leveled to promote even adhesion.

- Monitor Humidity: Use a hygrometer to monitor humidity levels in your printing environment.

- Store Filament Properly: Keep your filament in airtight containers or vacuum storage bags to prevent moisture absorption.

Wrapping Up

Warping and layer adhesion issues can be frustrating, but with the right techniques, they’re entirely preventable. By optimizing your bed temperature, controlling the printing environment, and choosing the right materials, you can achieve strong, warp-free prints every time. Don’t forget to experiment with slicer settings and post-processing techniques to further enhance your results.

Have you tried any of these tips to fix warping or improve layer adhesion? Share your experiences and results in the comments below!

FAQs

1. Why do my 3D prints warp?

Warping is often caused by uneven cooling, incorrect bed temperature, or using materials prone to shrinkage, like ABS.

2. How do I improve bed adhesion?

Use a heated bed, apply adhesives like glue sticks, or switch to a build surface like a PEI sheet. Ensuring proper bed leveling is also crucial.

3. Can I use PLA to avoid warping?

Yes, PLA is less prone to warping compared to ABS. For high-quality PLA, try this PLA filament.

4. Do I need an enclosure for 3D printing?

An enclosure is highly recommended for materials like ABS to maintain a stable temperature and reduce warping. Check out the Creality 3D Printer Enclosure.