Why Is My 3D Print Brittle? Causes and Solutions

Share

Why Is My 3D Print Brittle? Causes and Solutions

Introduction

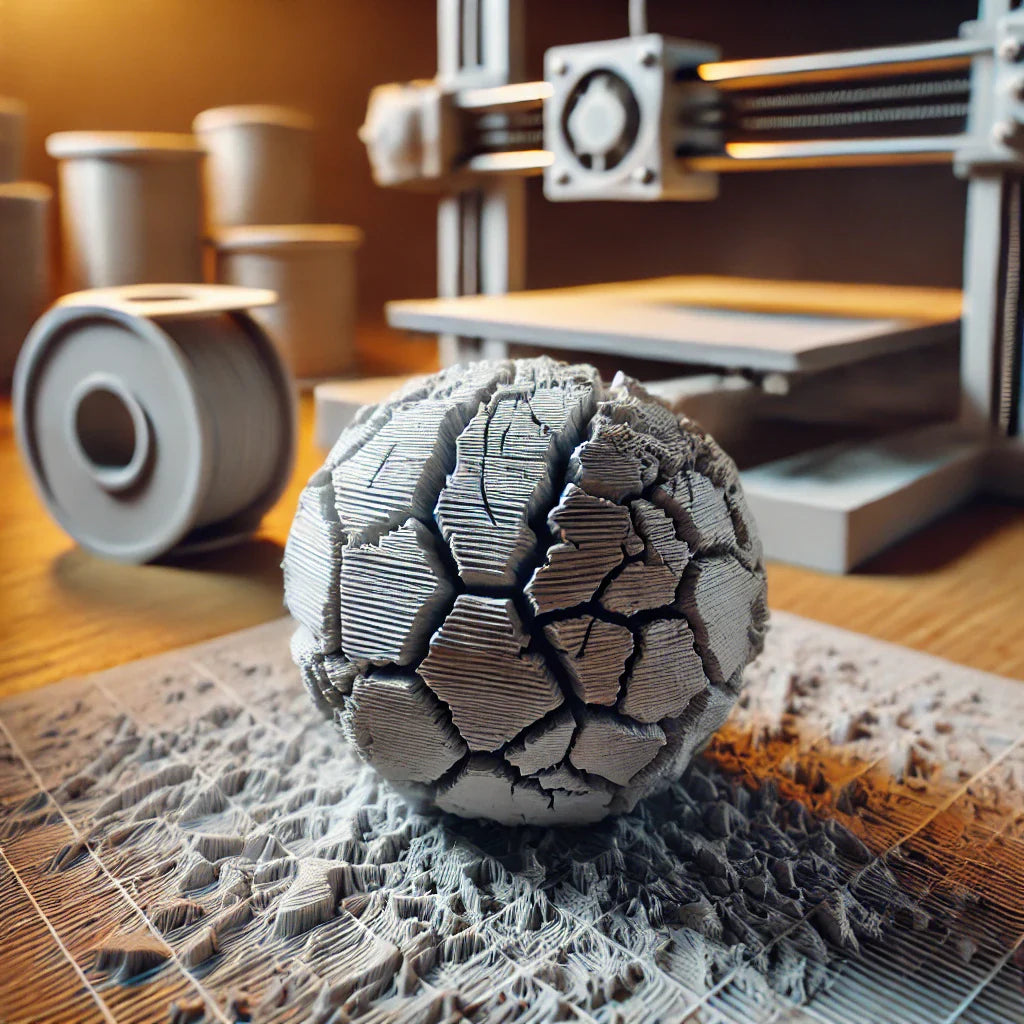

There’s nothing more frustrating than watching your 3D printer hum away for hours, only to produce a finished object that snaps at the slightest pressure. Whether you're creating functional prototypes, artistic designs, or hobby projects, brittle prints can derail your progress. If you're wondering why your 3D prints are so weak or how to fix brittle 3D prints, you're in the right place. Brittle 3D prints are a common problem, but with the right knowledge, you can transform your fragile prints into durable and resilient items. Let’s dive into the causes and solutions to ensure your prints are as strong as they are stunning.

What Makes 3D Prints Brittle?

1. Material Quality and Type

Low-Quality Filament: Cheap or poorly stored filament can absorb moisture from the air, leading to poor layer adhesion and brittleness. Always opt for high-quality filaments like Hatchbox PLA or Overture PETG.

Wrong Material for the Job: Not all materials are created equal. For instance, PLA is less tough than ABS or PETG and might not be suitable for mechanically stressed parts. Consider using tougher materials like Polymaker PolyTerra PLA or TPU for flexible parts.

2. Printing Parameters

Extruder Temperature: Too low a temperature can prevent layers from bonding well, whereas too high a temperature can degrade the material. Use a temperature tower to find the optimal setting for your filament.

Print Speed: Faster speeds can lead to insufficient layer bonding, making the final product brittle. Slower speeds are often better for intricate or high-strength parts.

Layer Height: Thicker layers might not adhere well to each other, contributing to a weak structure. Experiment with smaller layer heights for better bonding.

3. Environmental Factors

Humidity: High humidity can make materials like nylon and PLA absorb moisture, which drastically reduces their strength. Store your filaments in a dry, cool place using a Sunlu Filament Dryer or vacuum-sealed bags with desiccants.

Temperature Fluctuations: Consistent printing environment temperatures are crucial. Variations can lead to uneven cooling and thermal stresses. Consider using a Creality 3D Printer Enclosure to maintain a stable environment.

How to Prevent Brittle 3D Prints

1. Optimize Material Handling

Store Filaments Properly: Keep your filaments in a dry, cool place, preferably in sealed bags with desiccants to avoid moisture absorption. Check out these vacuum storage bags for long-term storage.

Choose the Right Material: Match the filament type to the project requirement. Use tougher materials like ABS, PETG, or specialized filaments for parts requiring higher durability. For example, Overture PETG is a great choice for functional parts.

2. Fine-Tune Your Printer Settings

Adjust the Extruder Temperature: Find the optimal temperature for your material. This might mean a few test prints, but it’s worth tuning.

Calibrate Print Speed: Slower speeds might be necessary for better layer adhesion, especially for intricate or high-strength parts.

Layer Height and Wall Thickness: Increase the wall thickness and adjust layer height for improved strength. Smaller layers can bond better, creating a sturdier object.

3. Control the Printing Environment

Maintain a Stable Environment: Use an enclosure like this Creality 3D Printer Enclosure to keep out drafts and stabilize the temperature around your printer.

Dehumidifiers for High Humidity Areas: If you live in a moist climate, using a dehumidifier can protect both your filaments and the print process. Monitor humidity levels with a hygrometer.

Expert Tips for Stronger 3D Prints

1. Post-Processing

Annealing PLA: Heat-treating PLA prints in an oven can significantly improve their strength.

Coating Prints: Apply a layer of epoxy resin to your prints for added durability and a polished finish.

2. Test and Iterate

Each printer is different. Continuously testing and tweaking settings based on print results can lead to optimal outcomes. Use calibration tools like Teaching Tech’s Calibration Website to fine-tune your printer.

3. Upgrade Your Filament

Invest in higher-quality filaments like Prusament PLA or Polymaker PolyTerra. The initial cost is higher, but the results are worth it in terms of durability and print quality.

Wrapping Up

Brittle 3D prints can be a thing of the past with the right materials, optimized printer settings, and controlled environmental conditions. By understanding the underlying causes and applying the above solutions, your prints will not only look better but also last longer. So, next time you set up your 3D printer, consider these tips to ensure strong and durable prints.

Ready to leave brittleness behind and move towards reliable and resilient 3D printing? Let these strategies guide your next print job towards success! Have you tried any of these tips to fix brittle prints? Share your experiences and results in the comments below!

FAQs

1. What is the best filament for strong 3D prints?

ABS, PETG, and TPU are generally stronger and more flexible than PLA, making them ideal for functional parts. Check out Overture PETG for a great option.

2. Can increasing the infill percentage make a print less brittle?

Yes, higher infill settings can help, but it's important to balance this with proper layer adhesion to avoid internal stresses.

3. Is it necessary to use a printer enclosure?

For materials sensitive to temperature like ABS, an enclosure helps maintain consistent temperature and reduces warping and brittleness. Consider this Creality 3D Printer Enclosure.

4. How does a clogged nozzle affect print strength?

A clogged nozzle can cause under-extrusion, leading to weak layer adhesion and brittle prints. Regularly clean your nozzle to ensure consistent material flow.