How to Fix Stringy 3D Prints: Effective Troubleshooting Steps

Share

How to Fix Stringy 3D Prints: Causes and Solutions

Introduction

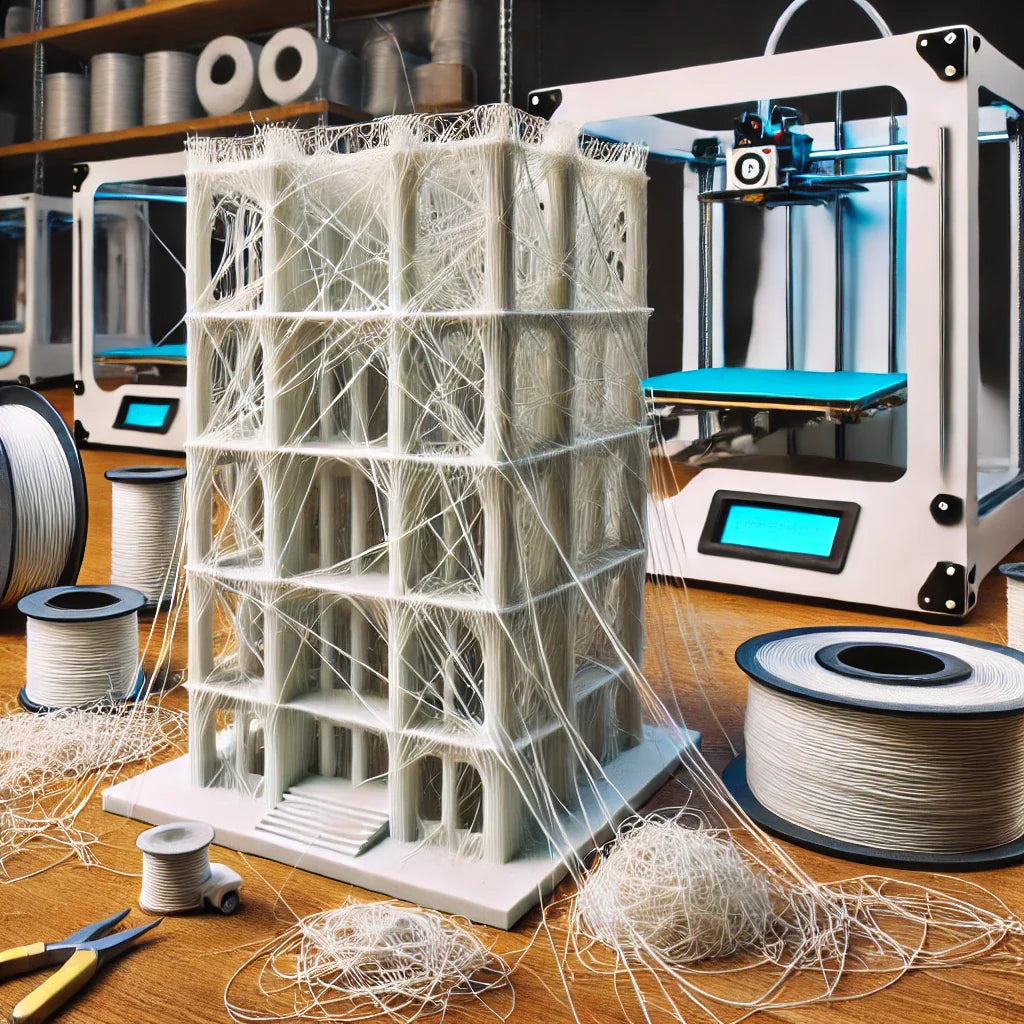

Stringy 3D prints, often referred to as "stringing," can be a nuisance for anyone in the 3D printing community. This phenomenon occurs when excess plastic strings between parts of a print, similar to a spider web. It primarily happens during travel moves when the nozzle moves over an open part of the print without extruding filament. If you've encountered this, fret not—here’s how to get back to crisp, clean prints!

Understanding the Causes of Stringing

Before we jump into solutions, let's pinpoint what leads to stringing:

- Excessive Temperature: Higher than necessary printing temperatures can make the filament too fluid, causing it to ooze out of the nozzle during movements.

- Incorrect Retraction Settings: Retraction pulls filament back into the nozzle when it moves across open spaces. If retraction is too low, stringing occurs.

- Print Speed: Too fast a print speed can also lead to inadequate time for the filament to cool, resulting in strings.

- Material Properties: Some materials like PETG and TPU are more prone to stringing due to their properties.

Step-by-Step Troubleshooting Guide

1. Adjusting Temperature Settings

Lower the Nozzle Temperature: Begin by reducing the nozzle temperature in small increments (about 5°C at a time). Watch if the stringing decreases without compromising the quality of your print.

Test Temperature: Perform a temperature tower test to find the optimal setting for your specific filament.

2. Refining Retraction Settings

Increase Retraction Distance: Start by increasing the retraction distance slightly. For many printers, a retraction distance of 0.5-2mm is typical, but some might require up to 6mm depending on the filament type.

Adjust Retraction Speed: Increasing the retraction speed can help pull the filament out of the nozzle quicker, preventing oozing. A good speed to start with is around 25-45mm/s.

3. Optimize Printing Speed

Find the Sweet Spot: If your printer is running too fast, it can lead to stringing. Try reducing the speed by 10-20% and observe the results.

Balance Speed and Quality: It’s important to balance speed with the quality of your print. Too slow may not necessarily solve stringing and could even affect other aspects of print quality.

4. Selecting the Right Material

Choose the Right Filament: If stringing continues, consider switching to a filament less prone to this issue. PLA tends to string less compared to PETG or TPU. Check out high-quality PLA filament for better results.

Dry Your Filament: Moisture in filament can cause stringing. Ensure your filament is dry by storing it in airtight containers or using a filament dryer.

Practical Tips to Keep in Mind

- Use a Nozzle Cleaning Technique: Regularly clean your nozzle to prevent any accumulated filament from contributing to stringing. Consider using a nozzle cleaning kit.

- Implement a Cooling Fan: Improve part cooling by using or upgrading your printer’s cooling fan, which helps solidify the filament faster after it exits the nozzle.

- Fine-Tune with Test Prints: Always use test prints like calibration cubes or stringing tests available online to fine-tune your settings without wasting much material.

Wrapping Up

Fixing stringy prints may require a bit of patience and tweaking, but by systematically addressing the temperature, retraction settings, print speed, and material choice, you can greatly improve your results. Remember, each filament and printer is different, so what works for one setup may not work for another.

Have you tried any of these tips to fix stringy prints? Share your experiences and results in the comments below!

FAQs

1. Why is my 3D printer leaving strings?

Stringing is often caused by excessive nozzle temperature, incorrect retraction settings, or using materials prone to oozing like PETG or TPU.

2. How do I stop my 3D printer from oozing?

Adjust your retraction settings, lower the nozzle temperature, and ensure your filament is dry. Using a filament dryer can help.

3. What temperature should I use to avoid stringing?

Perform a temperature tower test to find the optimal temperature for your filament. Start by reducing the nozzle temperature in small increments.

4. How do I dry 3D printing filament?

Store your filament in airtight containers or use a filament dryer to remove moisture.